Tips & Tools to Boost Warehouse Labor Productivity

Labor costs can comprise 50-70% of all warehouse operating budgets. Are you getting the most from your labor dollars?Improving profitability is top of mind for every company owner and C-level executive. Improving profitability is not just about cutting costs and creating efficiencies. It is also about maximizing the use of resources. One of the most costly resources in any warehouse is your workforce. How can you better utilize your labor resources to improve the financial performance and operations management of your company?

Use the Value of Your Workforce to Differentiate Your Business from That of Your Competitors

First, consider the

Enable your workforce, from top to bottom, to think and act as if they are a valued extension of each customers’ business and brand. Details matter. In today’s

8 Technology Tool Options to Help Improve Workforce Performance

Next, consider how using technology can maximize the effectiveness and productivity of the workforce you currently have.

- Wireless RF Mobile devices facilitate real time communication and collaboration across your warehouse operation. Much of warehouse operations is time sensitive. Getting the right message to the right person at the right time to handle the right process is mission critical. Investing in integrated systems that enable real time visibility of information and communication makes perfect business sense.

- RFID, is ideal for increasing the speed of receipt of goods; managing assets, product traceability, shipping and freight.

- Voice enabled solutions for picking, putaway, etc. helps to boost workforce productivity, reduce labor costs and reduce errors.

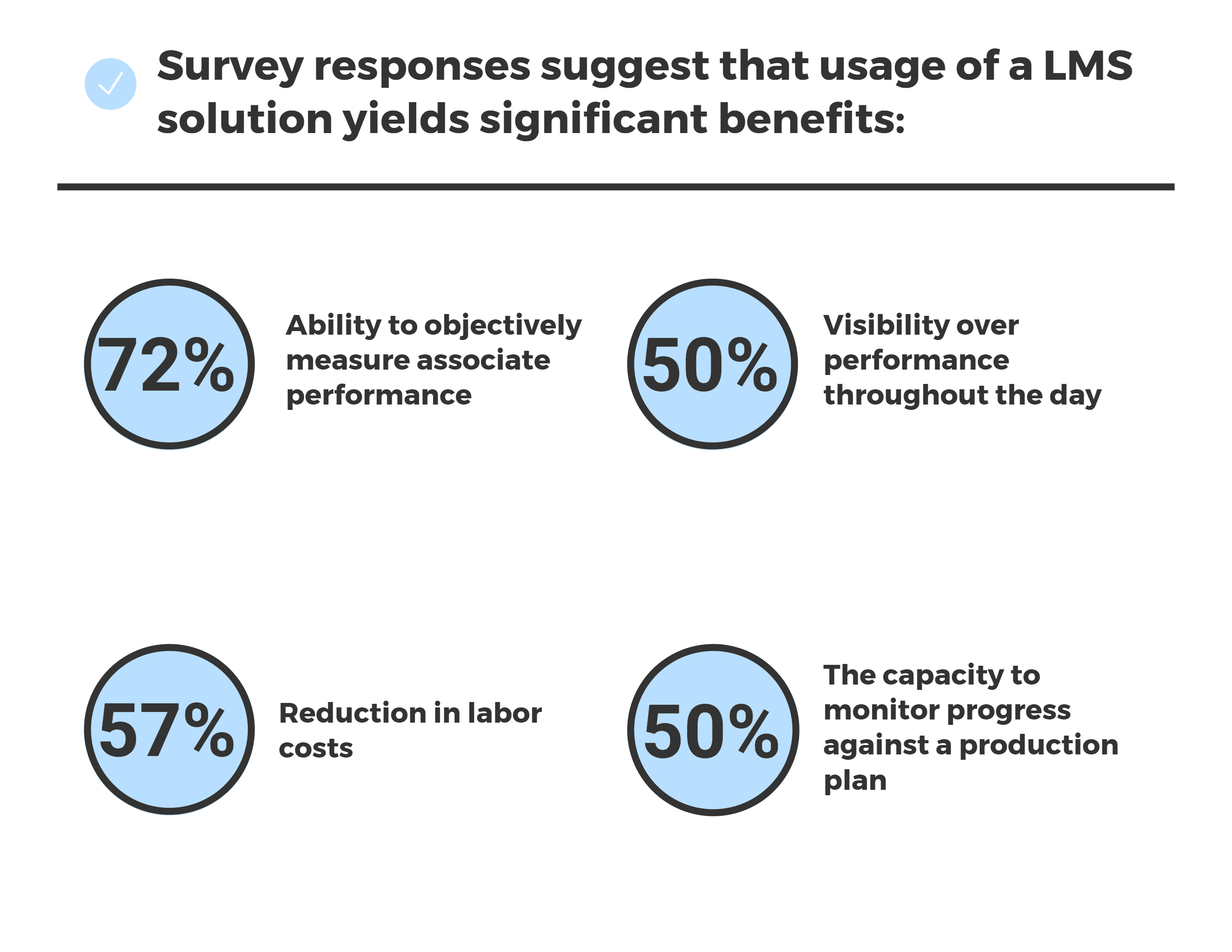

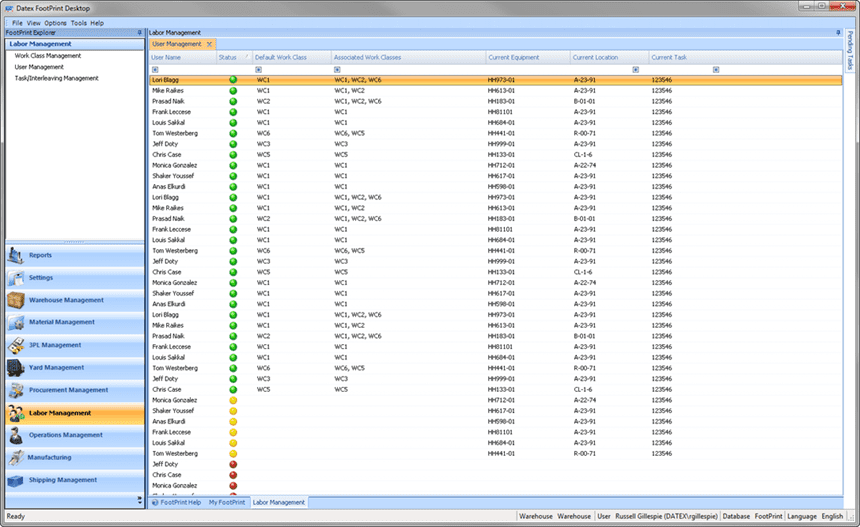

- Labor management system (LMS) enables your company to track and monitor each worker’s performance, schedule work and produce reports to better manage and train your workforce as well as aid in operations planning. LMS software is now frequently used by distribution centers and third party logistics providers to measure performance against labor standards. Engineered standards help to provide a baseline productivity measurement against which efforts can be measured.

- Wearable devices leaves hands free to enable warehouse workers to be more productive. Not only are wearables great for boosting labor productivity but also for reducing errors. A 2016 study by Zebra revealed that wearable tech can increase labor productivity in the warehouse by up to 15% and reduce errors by 39%

- Workflow-based WMS reduces time consuming, error prone processes so that workers can spend less time making decisions and more time completing operations based on established requirements and methodologies. A warehouse management system that is workflow-based can also improve labor productivity, help to reduce labor costs and aid in task management for warehouse labor.

- Cartonization software (for warehouse management system) enables automated selection and packing methodology to properly pack goods for shipment. Use of a cartonization module for WMS reduces the burden on labor and also decreases decision making, time and the cost of packing materials.

- Pick-to-light, put- to-light, light-directed systems as well as material handling systems can be used to enhance the capabilities of your labor resources. This can be especially useful for fast-paced operations, especially those with multi-lingual workforces

7 Tips to Build a More Effective Long Term Workforce

- Pair seasonal/temporary warehouse workers with experienced team members or add them to established work groups. This will make the best use of the expertise of the experienced workers. This will enable them to be seen as having a higher status and position them to mentor other workers and help generate increased productivity.

- Assign a “buddy” to each new worker. Choosing a top performer in warehouse operations will improve the odds that the new warehouse worker will be motivated and receive the needed on the job training in a way that will be easier to absorb, learn and master.

- Be sensitive to age and cultural differences and sensitivities. Introducing new warehouse workers to others of similar backgrounds can make them more comfortable and improve their acceptance when working as a team. Older workers have specific challenges and needs. Take the time to understand their limitations and possible needs for accommodation in the warehouse facility environment.

- Teach basic words and phrases in foreign languages most used around your warehouse to English-only workers. This will help your entire workforce communicate better, improve teamwork across your organization and make non-English speaking workers feel welcome and comfortable.

- Maintain an employee-focused, equitable mindset. Instead of focusing on employees as “labor” or mere commodities, shift your focus to learning and development. By concentrating your efforts to make sure that your workforce remains interested in their work, motivated and team-oriented, your company will be better able to retain a quality workforce.

- Invest in hours of training before putting a warehouse worker on the floor. Making sure that every warehouse worker feels comfortable and knowledgeable enough to work on the warehouse floor before they do so for the first time shows the individual that you are investing in their success. This will be helpful in reducing the stress level on the worker, help to reduce errors and wasted time and may even result in a productivity gain.

- Training is an investment in the future of your business. Train, train, train! According to a poll by Louis Harris & Associates, 41% of companies with poor training programs lose employees during their first year of service

Using a Labor Management System to Help Improve Workforce Productivity

Multi-Task Interleaving:

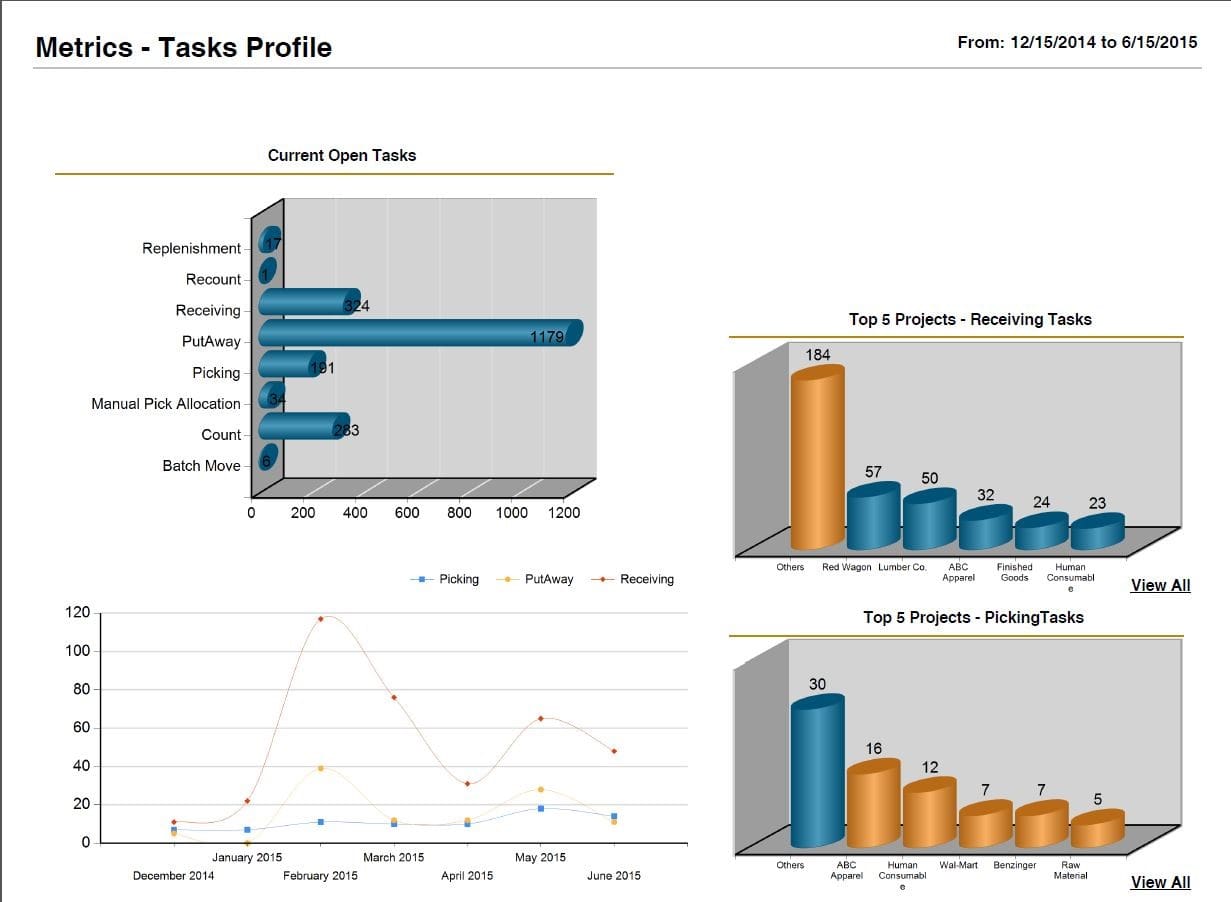

Warehouse Task Management:

Depending upon the labor management system, users may be able to manually assign tasks to warehouse workers or have the system assign them automatically.

Using LMS capabilities, many companies now use performance data for coaching and mentoring as well as to develop warehouse worker incentive pay programs, performance bonuses and other rewards in order to encourage improvement, accuracy and greater productivity.

Workforce Management:

Critical for management and planning, having a labor management system can enable you to keep track of each member of your workforce as well as the equipment being used, work classification of each worker based on the type of work qualified to do, location and task being performed. Automated workforce management functionality can help ensure that processes are carried out as scheduled. This helps to minimize wasted time and increase the accuracy and efficiency of operations.

Labor Management System Reports and Dashboards

The best labor management systems are those that enable users to create customized reports and dashboards in any format. Many companies now use easy-to-read weekly dashboards that they develop for each warehouse worker and displays each report on a wall for the entire workforce to view. This enables all workers and teams to compare their performance, gauge the effectiveness of their practices against that of other workers and ensures transparency. Warehouse employees are typically encouraged to discuss performance and to provide feedback to the company and ideas for process improvement.

Providing data in an open format helps to encourage communication and to build trust between the workforce and your company’s leadership team. When handled properly, this can lead to open, honest dialog, better decision making and team building within the organization.

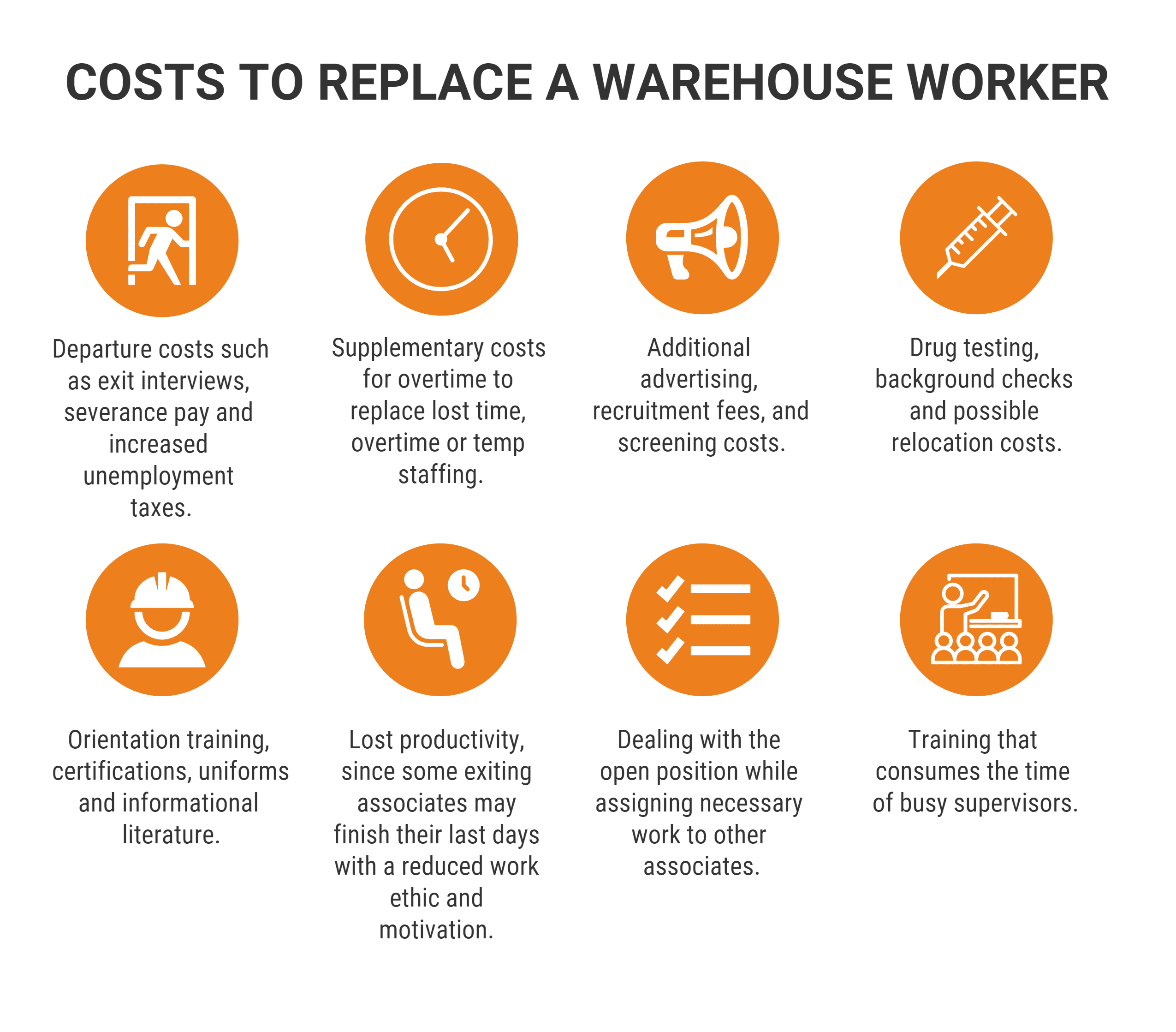

Reduce Labor Costs by Minimizing Turnover & Building a Stronger Long Term Workforce

- Separation costs: exit interviews, severance, increased unemployment taxes

- Overtime costs: overtime to replace lost time or temporary staffing costs

- Recruitment costs: advertising, recruitment fees, screening costs

- Pre-hire screening costs: background checks, drug testing

- Relocation costs: relocation expense

- Orientation costs: training, certification, uniforms, manuals, informational literature, training guides, etc.

- Lost productivity: some exiting workers may complete their final days at a slower pace with less effective, accurate operations

- Reduced productivity: need to cover the work of the open position by assigning work to other workers

- Training time: takes up time of supervisors, mentors and other workers

- More absenteeism and reduced quality, accuracy and efficiency during initial period of employment

Harder to measure and quantify, when experts consider these intangible costs, some estimate the cost of warehouse worker turnover to be up to 150% of salary. For one warehouse worker, that is a negative impact of $7,000- $42,000 on the bottom line of your business.

How Can You Reduce Warehouse Worker Turnover?

- Hire the right people

- Make sure workers have solid “soft” skills such as positive attitude, good communication and teamwork skills

- Pay a fair wage

- Provide competitive benefits

- Include some perks

- Establish reasonable expectations

- Provide ongoing training and mentorship

- Monitor performance

- Communicate clearly and frequently about performance

- Recognize achievement

- Reward progress and exceptional performance

- Provide a clear career path in your organization

- Provide opportunities to rise above-become a mentor, trainer, etc.

- Make workers more valuable by cross-training them in other functional areas of your operation

- Continue to provide additional training for continuous improvement and in other areas of your business and industry:

- CSCMP SCPro™ Certification

- CSCMP Online Education

- LINCS Supply Chain Management (low cost certification program)

Conclusion

Whether you are a third party logistics provider or distribution center, improving the financial performance of your warehouse operation can be done by recruiting, training and retaining the appropriate warehouse workers and using technology for labor productivity gain. By creating and developing a culture of excellent, accurate, timely service for your customers, your business will encourage exceptional workforce performance and be better positioned to attract and retain new business.

Some of the top technology options to help boost labor productivity

Estimated to be up to 25% of salary for hard costs, the cost of replacing a warehouse worker can have a direct impact on profitability. Having a solid, measured plan and executing effectively to recruit, train & develop warehouse workers is critical in keeping costly workforce turnover under control.

What Makes Datex Different?

1. Revolutionary low code/no code flexible workflow-driven warehouse management software

2. Most configurable, user-friendly WMS on the market today

3. End-to-end solution provider: software, hardware, EDI, and managed services

4. White Glove Concierge Service

5. Executive-level attention and oversight