Datex Warehouse Management System

It’s a Fit! Tailor-Made for Your Business

Our workflow-driven software uses visualization tools to help us diagram processes, incorporate business logic and decision making to create smooth, seamless flows of activities that can be automated. The automation element removes the need for warehouse workers to determine a course of action and act upon decisions. No more manual workarounds, errors or wasted effort.

Datex experts gather the software requirements during collaborative work sessions with each client then configure the software to meet business needs.

Why Select Datex?

Configurable WMS reduces costs, errors, and wasted time

Workflow-driven software ensures maximum flexibility

Readily configurable WMS ensures “best fit” for your operation

Tailor reports and dashboards to meet your needs

Your choice of Cloud-based system, SaaS, or hybrid

Wraparound care from implementation to support

Executive-level attention and oversight

End-to-end technology solution provider

Dedicated Customer Success team provides white glove service

Handles any kind of inventory including bulk, regulated and hazardous goods

Special Datex Warehouse

Management System Features

Configuration

Make changes to processes without custom programming

"Drag & Drop" Reporting

Saves time and money on customizong reports

Audit Trail

System audit trail enables comprehensive traceability

Customization

Suite of user friendly features to customize screens and views

Workflow-based System

Enables faster implementation & scalability

Crossdock & Transload

Crossdock & Transload on one screen saves time and reduces errors

Implementation & Support

Services provided by Datex employees, not third parties

User Friendly

Intuitive user friendly system that is easy to learn, use and master

Who This is for:

- Third party logistics (3PL) including

○ 3PL fulfillment

○ 3PL transportation services

○ 3PL pharma

○ 3PL cold storage warehousing

- Private cold storage warehousing

- Pharmaceutical and healthcare

- Distribution centers

- Fulfillment centers

- Omnichannel

- E-commerce

- Food and beverage

- CPG

- Retail and wholesale

- Wholesale distribution

Types of “Warehouse” Facilities That Can Use Datex WMS:

- Facilities that store, handle, process inventory including:

- Fulfillment centers

- Distribution centers

- Terminals

- Temporary supply chain business operations that hold inventory

- Pop-ups

- Micro-warehouses

- Facilities “in transit”

Benefits of Using Datex Warehouse

Management Software

WMS that is easy to learn, helps increase user adoption

Ability to customize reports, processes & more saves costly fees

Automated workflow driven system enables greater efficiency & accuracy

WMS enables businesses to compete & win new business

Specialized features enable labor and time savings

Real time reporting facilitates better decision making

Enhanced management process controls

Optimized workforce resource planning

Complete visibility across multiple warehouses

Multi-task interleaving minimizes wasted labor

Improve warehouse storage capacity

Decrease manual handling operations significantly

Reduce errors by nearly 99%

Warehouse Management System Features

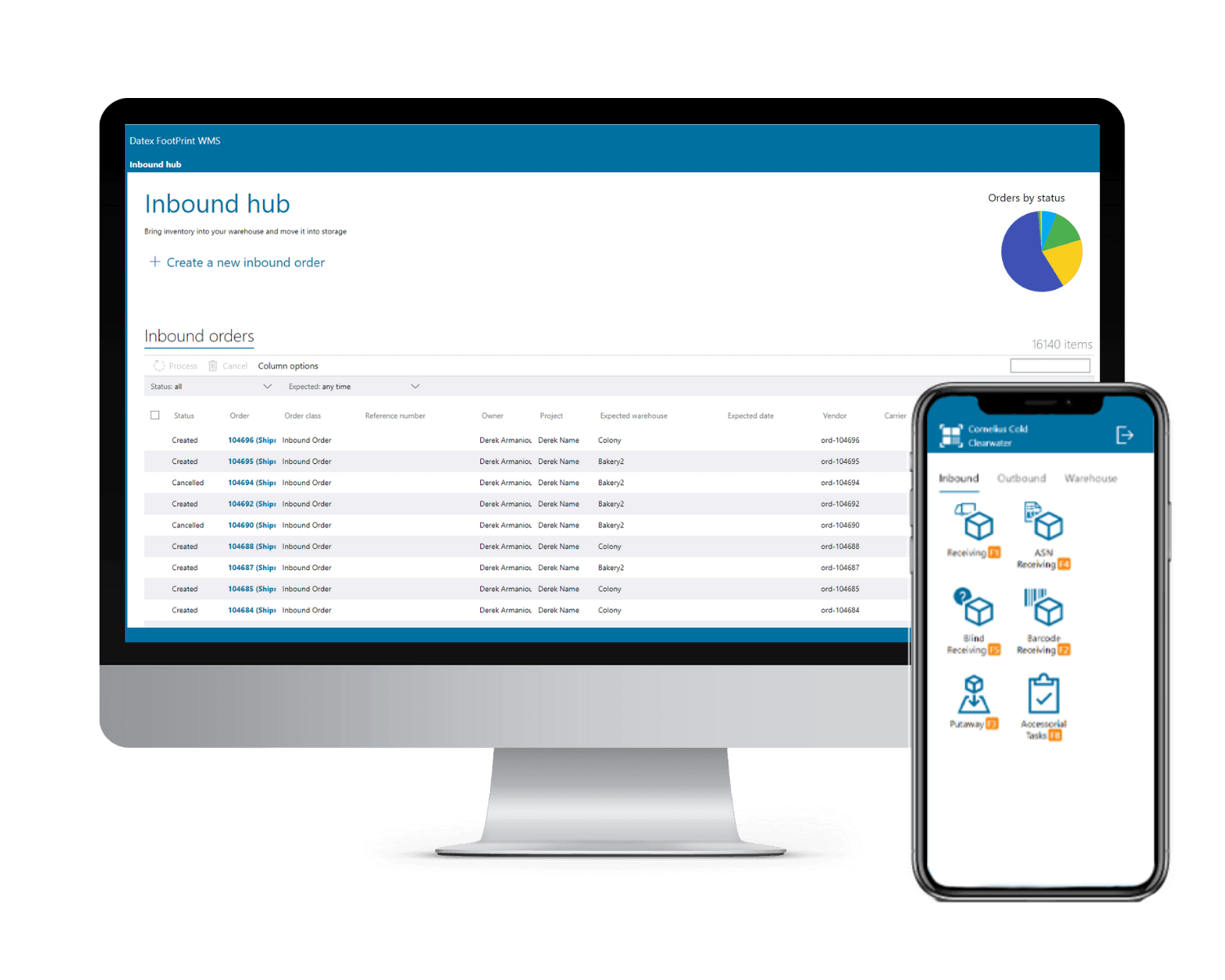

Datex Footprint WMS was developed “from the ground up” using industry best practices. Our cutting-edge WMS is highly reliable and can handle heavy transaction volume and large numbers of users without “locking up”.

RECEIVING

- Blind receiving

- Partial blind receiving

- EDI/ASN receiving

- Bulk receiving

- Automated receiving

- Weigh system scale ticket automated to WMS

- Catch/variable weight

WAREHOUSE OPERATIONS

- Pallet tracking

- Cycle counting

- Barcode parsing

- Warehouse transfer

- Owner/cloaked owner transfer

- Restrict inventory locations

- Create customer specific labels & BOL

- Temperature capture

YARD MANAGEMENT

- Load/Container Management & Tracking

- Date available, last one date, last pier date, in yard date

- Tracks temperature readings

- Enables users to prioritize loads

- Tracks & manages imports and export containerized loads

- Check in/ check out

- Dock Door Appointment Scheduling

- Color coded appointment status

PUTAWAY

- System directed putaway

- User directed putaway

- Two-step putaway

QUALITY ASSURANCE/ QUALITY CONTROL WMS

- Multiple simultaneous holds

- Inspections

- Taste testing

- Quarantines

IMMUTABLE COMPREHENSIVE AUDIT TRAILS

- Ideal for helping to ensure proper documentation needed for regulatory compliance

PICKING & OUTBOUND PROCESSING

- Single order picking

- Batch picking

- Cluster picking

- Wave picking

- RF picking

- Bulk picking

- Pick by each

- Pick and pack processing

- FIFO, FEFO, FMFL, LIFO & more

ADDITIONAL WMS FEATURES

- EDI ready

- Configurable reporting

- Document storage in inventory records

- Comprehensive audit trail

- Signature capture

- Validation services available

- RF ready

- Workflow driven processes

TRACK INVENTORY

- Full traceability of warehouse inventory

INVENTORY MANAGEMENT

- Serialization/serial number control

- Automatic replenishment

- Track and trace

ORDER MANAGEMENT

- Provides complete inventory & order details

- Manage fill rate and backorders

- Order consolidation

- Apparel matrix available

LABOR MANAGEMENT

- Task interleaving

- Allocate, track, and monitor labor resources

- Real time workforce visibility

- Labor forecasting and scheduling

- Task time tracking

- Single screen workforce management visibility

- Auto or manual assignment of tasks

- Single tab mobile user task history

REAL TIMME DATA CAPTURE TRANSFORM OPERATIONS AND DECISION MAKING

- Seamless inventory tracking

- Transparent stock levels

- Leveraging barcode scanning ensures real time visibility

ACCOMODATES EVEN THE MOST COMPLICATED WAREHOUSE PROCESSES AND STRATEGIES

- Omnichannel

- Complex order fulfillment

- Multiple picking strategies

WMS VENDORS ARE NOT ALL ALIKE

As a Microsoft Gold Partner and award-winning software vendor, Datex works hard to continually improve our software solutions with input from our clients, partners, and others in the industries we serve. No matter the company size or type of warehouse inventory, Datex is the ideal choice for best-of-breed warehouse management software. As a supply chain software developer, Datex has been vetted and acclaimed by Microsoft for our exceptional service and high-quality software development. Our WMS is considered one of the top warehouse management software solutions on the market today.

Summary

Critical to warehouse operations, the Datex warehouse management system can be integrated to other vital systems including enterprise resource planning systems (ERPs) and transportation management systems (TMS), as well as to web stores, marketplaces, shipping carriers, CRM, labor management systems and much more. Today, the integrated warehouse is a reality. Connecting to many different systems and technologies including robotics and automation, material handling solutions,

The Datex warehouse management solution can be configured to meet the individual needs of each facility- no matter how each warehouse operates. Whether inventory is picked and packed or handled on a per pallet basis, our WMS can help save your company reduce costs and errors and ensure peak performance. Most Datex clients leverage their WMS investment to give their warehouse advantages over competitors.

Designed to be easy for warehouse workers to learn, use and master, our software automates warehouse processes, effectively making them foolproof. Whether using it for barcode scanning to check stock levels, for pick pack and ship operations or simple cycle counts, Datex Footprint WMS streamlines processes for warehouse workers. The result is top performance.