The DSCSA Pharmaceutical Serialization Deadline Looms

Pharmaceutical serialization impacts your entire operationFrom the United Kingdom to the United States, Canada

DSCSA was developed to help make drug products safer. This FDA regulation creates a framework for enabling pharmaceutical product traceability. This will help companies across the pharmaceutical supply chain identify, isolate and restrict counterfeit drugs from affecting the health and safety of consumers. In order to create this framework, DSCSA requires each individual unit of a pharmaceutical product to have a unique product identifier. This unique product identifier or serial number will be linked to vital information about the origin of the product, the pharma product batch number when it was manufactured and the expiration date. This will enable individual pharmaceutical products to be traceable from the point they are manufactured to the point of final dispensation to the consumer (patient).

All prescription drugs sold in the United States are required by FDA regulation DSCSA to be serialized at both the individual (saleable unit) level as well as at the case level.

Key objectives of the Drug Supply Chain Security Act were designed to provide track and trace of drug

DSCSA Product Identification (Pharmaceutical Serialization)

Many companies across the pharmaceutical supply chain have questions regarding the FDA DSCSA regulations involving a “unique product identifier” on certain prescription drug packages.

According to DSCSA a product identifier :

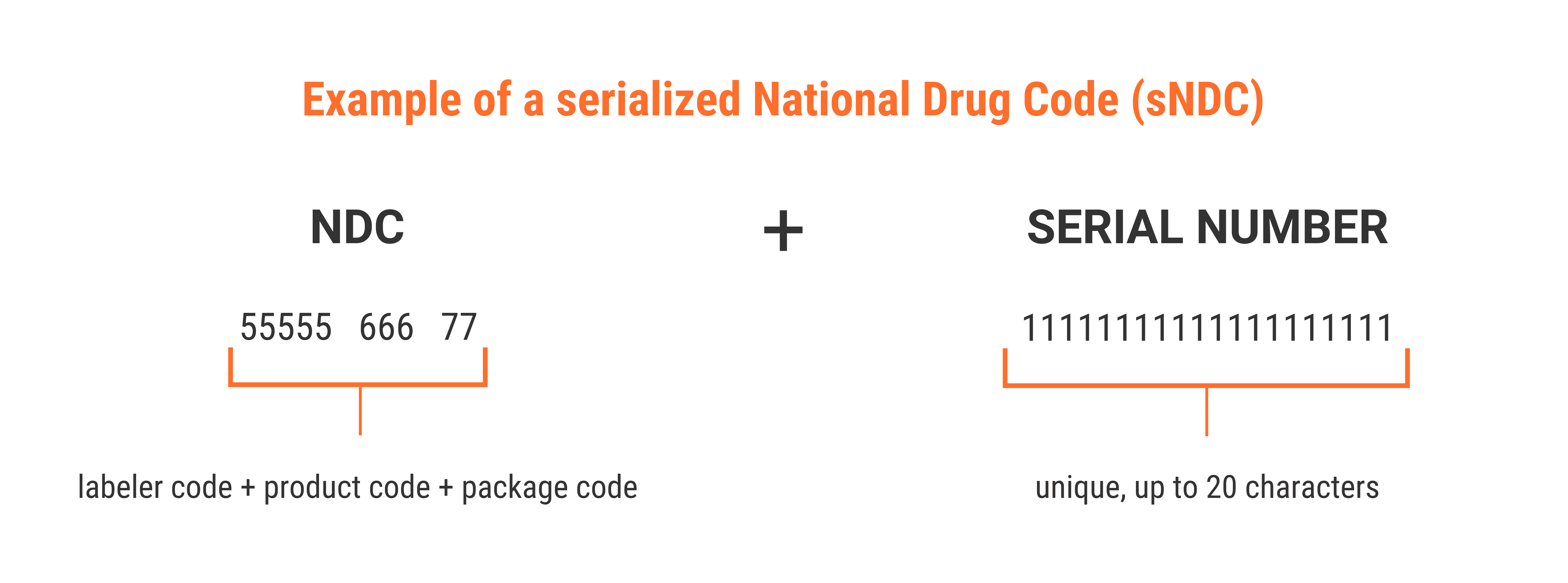

- Consists of a standardized numerical identifier: NDC, serial number, lot number

and expiration date. This is sometimes referred to as the SNDC or Serialized National Drug Code. - Must be in both human and computer readable format

The two most recognized ways to implement package level Standardized Numerical Identifiers (SNI) for prescription drug products involve use of NDC + a serial number or use of a GTIN which incorporates NDC + a serial number. Lot number and expiration date are also required.

National Drug Code (NDC):

The National Drug Code, identified on packages with the letters NDC, is the unique 10 digit 3-segment number that acts as a universal product identifier for human-grade pharmaceutical products in the United States. An NDC is present on a prescription and non-prescription (over-the-counter) medication packages and inserts in the United States. NDC codes are used to bill healthcare claims and may need to be converted from a 10 digit code to an 11 digit format for billing purposes. Manufacturers and re-labelers use the NDC to submit registration and drug listing information to the FDA electronically.

NDC nomenclature:

- First 3 numbers identify the LABELER: manufacturer, packager or distributor. This code is assigned by the FDA.

- Second set of numbers identify the PRODUCT CODE: Assigned by the labeler, the product code which identifies the specific strength, dosage form (liquid, capsule, tablet, etc.) and formulation of a drug for a specific manufacturer.

- Third set of numbers identify the PACKAGE CODE: Assigned by the labeler, the package code which identifies the package types and sizes.

GTIN vs. NDC

Although there is currently no product identifier used by 100% of the pharmaceutical industry, the top 3 wholesale pharmaceutical distributors have chosen to align to the GS1 standard. If you already have an NDC, you should obtain a GTIN to use your NDC in GS1 barcodes including the U.P.C. barcode, GS1 DataMatrix and data sharing standards including EPCIS. It is not necessary to register individual GTINs with GS1. The FDA does not require registration of GTINs or have a requirement in DSCSA for any additional registration of the NDC beyond the original requirement. GTINs are used in reporting transaction information and transaction history when ownership of individual instances of pharmaceuticals are transferred in the supply chain.

GTIN is the GS1 Global Trade Item Number, an established, recognized identification system used across the world in many industries. To obtain a GTIN, you must register with GS1. First, become a GS1 member by registering your labeler code with GS1. GS1 then turns your labeler code into a company prefix which is the base for the GTIN.

GTIN is different from the NDC as it is used to identify goods for trade other than pharmaceuticals, medical devices, etc. around the world. The GTIN not only identifies the individual saleable unit but also higher-level groupings. This includes homogeneous cases, homogeneous pallets, etc. As compared to the NDC number, a GTIN would be unique such as for a 60 capsule bottle of a drug versus a 12 bottle case of the same drug which would have a different GTIN. The NDC identifies the drug, however it makes no distinction between the individual saleable unit and higher-level groupings.

The NDC is utilized exclusively for drug identification subject to U.S. FDA regulations. However, drug trade items can be given a GTIN which embeds the NDC. This is considered to be a best practice. Individual saleable units can have the NDC embedded in a GTIN-12 by combining the following items in left-to-right order in this way:

- The digit “3”

- The 10-digit NDC

- A check digit which is computed from the previous 11 digits according to GS1

DSCSA and GTIN

The DSCSA mandates creation of a traceability system which necessitates frequent, accurate massive amounts of data being exchanged between pharmaceutical industry trading partners. To make this feasible, both the FDA and DSCSA suggest that the industry utilize standards which comply with a form and format developed by a widely accepted international standards organization.

What is GS1?

In 1973, the grocery industry united to adopt the UPC barcode to improve the speed and efficiency of retail check out. This began the mission of establishing a standard to enable information to be shared uniformly across all sized businesses. GS1 Standards are the most widely used system of standards worldwide. GS1 standards help ensure clear, effective communication, enabling more accurate, timely sharing of information.

GS1 standards are essential across the supply chain logistics industry and play a vital role in minimizing waste, ensuring safety and providing a framework for real-time tracking, traceability and supply chain optimization. GS1 maintains numerous standards. In 2003, GS1 began an initiative designed to innovate and establish industry-driven standards for the Electronic Product Code™ (EPC). This supports the use of Radio Frequency Identification (RFID) and facilitates global visibility of items EPC Information Services (EPCIS).

Many pharmaceutical industry companies are embracing GS1 standards including using EPCIS for the data exchange that DSCSA requires. GS1’s EPCIS standards will then require

Using the GS1 standard, the GTIN repository would provide a single method for manufacturers to share consistent, accurate master data with downstream pharmaceutical supply chain partners. This would relieve the manufacturer of the burden of sharing the same data multiple times with multiple trading partners. GTINs would be submitted by manufacturers to the central repository. The GTIN repository would then become the source for GTIN and related product information.

SGTIN

SGTIN is a combination of GTIN as well as a unique serial number of up to 20 alphanumeric characters. Every instance of a respective trade item would receive a different serial number.

For example:

A particular GTIN may be assigned to a 30 capsule bottle of drug ABC. All of the 30 capsule bottles of drug ABC would have the same GTIN however, every individual 30 capsule bottles of drug ABC would have a different serial number and so a different STIN

Challenges in Pharmaceutical Serialization

1. Serialization May Require Label Redesign

Serialization may require redesign of labels to accommodate the new 2D barcode which can, in turn lead to alterations or redesign of graphic elements and packaging structure.

2. New Labeling May Impact Production Efficiency

The addition of label requirements will affect multiple packaging processes. Having to affix labels will slow down the packaging line, necessitating additional manpower or benefit from use of automated tools to maintain existing production levels.

3. IT Infrastructure and Data Management

Because of the sheer volume of data that must be collected and stored for 6 years, companies will need to carefully plan and execute a strategy to meet information technology needs. Making sure that your organization has the infrastructure, architecture, resources and tools to generate, store, capture, use and transmit millions of serial numbers for various supply chains is essential.

4. Serialization Impacts the Entire Operation

Because implementing product serialization is more than simply adhering a label to a package, it is important to organize and engage a cross-functional team to plan and execute your strategy for serialization. This will require input from the IT, processing and packaging operations, labeling, process and resources.

5. Financial Cost of Serialization

Serialization requires capital investment for items such as updating equipment, hardware, software, training and start up costs. Unforeseen costs such as diminished productivity, additional manpower and other factors also impact serialization project cost.

Conclusion:

With the impending DSCSA deadline approaching in November 2018, companies across the pharmaceutical industry supply chain are straining to learn more about serialization and to work towards compliance. Pharmaceutical companies affected by this change include manufacturers, repackagers and wholesale distributors.

Understanding that serialization is a process that involves an entire operation is critical. As the FDA pushes ahead, pharmaceutical manufacturers, repackagers and wholesale distributors are working to gain a handle on the cost of pharma serialization. Implementing serialization will mean rethinking life science packaging lines, packaging processes, data storage, labeling systems, operating software and global pharmaceutical supply chain regulations and needs. Proper planning and collaboration on execution by cross-functional teams working on serialization is essential for the success of the project.

What Makes Datex Different?

1. Revolutionary low code/no code flexible workflow-driven warehouse management software

2. Most configurable, user-friendly WMS on the market today

3. End-to-end solution provider: software, hardware, EDI, and managed services

4. White Glove Concierge Service

5. Executive-level attention and oversight