Leveraging Cross Docking to Reduce Costs, Damages, and Delivery Time to Consumers

Explore how companies can benefit from cross docking

This blog has a variety of things you should know that explain what cross docking is, its use in final mile delivery, and the benefits that it provides to businesses and consumers.

One of the most important tasks for shippers and suppliers is making sure that consumers get their products damage-free and just-in-time. E-commerce presents challenges to meeting these needs, however. Due to a shift in consumer buying habits, companies are expected to ship a high volume of goods via same day and next-day delivery. Because of this, 3PLs are under pressure to fulfill orders in fast, efficient, and cost-effective ways. To that end, the supply chain must be flexible enough to move items directly from one transport system to the next in a seamless transition.

Cross docking is useful for saving time. It is not a new concept, having been in use since the 1930’s when it was established by the US trucking industry. The circumstances now associated with the global market have given cross dock facilities a more valuable place in supply chain logistics. 3PL facilities and distribution centers are becoming more equipped to handle high volume product shipping. With enhanced visibility and automation that reduces or altogether removes warehouse management costs, 3PLs can move goods more effectively.

What is Cross Docking?

Cross docking involves the unloading of inbound products onto outbound trucks to be delivered directly to consumers or businesses. Goods are taken from one transportation vehicle to another without utilizing warehouse storage for holding. Cross docking usually takes place at warehouses called distribution docking terminals or cross dock facilities. Unlike normal warehouses, these terminals have minimal inventory storage space and do not store products long term.

The process is often used with LTL and retail shipping. In LTL trucking, cargo is moved from one transportation vehicle directly to another without utilizing any inventory storage space. It is cost-effective for LTL shippers because it makes use of fewer vehicles and reduces the storage costs and labor costs associated with receiving, put away, and inventory.

Retail cross docking utilizes staging areas inside terminals. 3PL services such as sorting, consolidating, and short-term storage are provided until the shipment is ready for distribution. Products are typically held 24 hours or less after arriving at docking terminals.

There are three different methods of cross docking:

- Continuous arrangement

- Consolidation arrangement

- Deconsolidation arrangement

Types of Cross docking

- Manufacturing

- Distributor

- Transportation

Reasons Companies Use Cross Docking

- Late Deliveries

- Mixed Freight

- Intermodal Transport

Continuous Arrangement

Products are transported to a cross docking facility and moved directly from inbound vehicles to outbound vehicles to be shipped directly to consumers.

Consolidation Arrangement

Multiple freight loads are combined into one full truck shipment load for transport. Products being held are also consolidated into the shipment.

Deconsolidation Arrangement

Large loads are broken down into smaller shipments and transported directly to consumers.

Using Cross Docking to Help Reduce Costs

The advent of e-commerce has made cross docking more useful than ever. Companies utilize it to reduce their need for inventory management and to improve their warehouse cost efficiency. It is an important supply chain practice because it reduces the amount of time products are handled. By consolidating incoming and outgoing cargo, it reduces:

Storage costs

Transportation costs

Material handling

Labor costs

Product damage

Delivery times

Post-COVID, the cost of cross docking has risen. Its rates and fees are impacted by labor needs, mode of transportation, and package complication. The more services that cross dock facilities must do to prepare products for just-in-time delivery, the higher delivery rates are. Cargo that does not have to be extensively handled is less expensive while packages that need sorting or storage are more costly. Cross docking is frequently used when moving time sensitive and perishable inventory, such as foods and beverages or pharmaceutical products. The process retains product shelf life and helps companies avoid having excess and dead stock inventory.

Order Fulfillment, Final Mile, and Cross Docking

The explosion of online purchases has resulted in faster order fulfillment. Fast delivery is no longer an added feature and is instead the norm and expectation. A recent study released by Peerless Research Group states that 52% of shipping companies currently use a method of cross docking. The companies state that these operations have improved their customer service and decreased supply chain related costs. Of the 52% of companies that utilize cross docking, 34% are currently outsourcing or plan to outsource cross docking processes. As specialists in logistics services, 3PLs equipped with the proper technology are primed to successfully implement cross docking practices.

Wal-Mart is the most famous case of supply chain cost reduction using cross docking. Wal-Mart utilizes cross docking by receiving, processing, and sending products on trucks to stores within 130 miles.

A concern for many shippers is final mile delivery. The final mile does not signify the delivery time; however, it does play a major role in delivery time. The time it takes for cargo to travel to a cross docking facility is important because it can cause issues for multiple shipments. 3PLs should be equipped with advanced logistics capabilities, especially if they are in highly populated areas. Localization of cross docking facilities allows goods to be closer to consumers which can improve last mile delivery and customer waiting times.

Cross dock facilities use the same equipment (docks, pallets, conveyor belts, forklifts) that traditional warehouses use. For that reason, the proper methods and practices must be in place for cross docking to be effective. 3PL facilities that utilize cross docking should have automated:

Material Handling Systems

Order Processing Systems

Warehouse Management Systems

Quality Control Systems

Advantages of Cross Docking

As an operational process, it is essential for shipping inbound and outbound cargo and can be utilized to benefit nearly any industry. Cross docking is especially efficient when shipping temperature-controlled, perishable, and high priority goods. Its ability to speed products to market, save on costly services, and improve inventory handling are key reasons why it is used. These goods do not need inventory storage, so their inventory costs are eliminated. In addition, it removes many picking and packing steps that can cause damages to products.

Cross docking is advantageous to the foods and beverages industry because it can be used to supply a steady and consistent flow of goods. E-commerce and retail companies benefit from its ability to move items swiftly and reduce inventory. As evidenced, it is more advantageous for businesses that specialize in high product turnover, rapid turnaround, and perishable goods.

Types of Companies that Benefit from Cross Docking

- Foods and Beverages Industry

- Consumer Goods

- Automotive Industry

- Chemicals

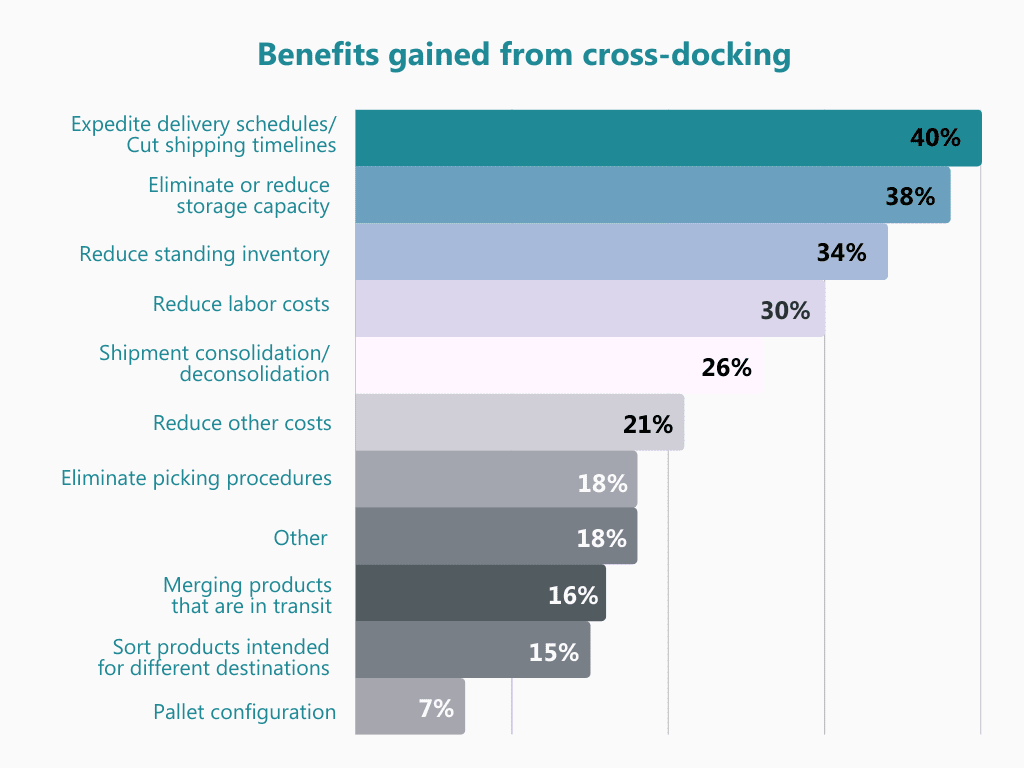

-Data by Peerless Research Group

Conclusion

Cross dock facilities are vital to supply chains across the nation and there are several reasons why businesses choose to utilize it. Besides reducing warehouse management costs, streamlined processes provide less room for error. This results in more efficient operations. Cross docking can be even more beneficial for companies when 3PLS pair it with their inventory management capabilities. Updated automation and end-to-end visibility can streamline logistics processes, increasing supply chain efficiency for single products or entire loads. These collaborative processes can provide a competitive advantage for 3PLs by:

- Increasing productivity

- Decreasing storage costs

- Satisfying consumers

Cross docking has numerous benefits for industries that supply high-volume and high-demand goods. It is one of the best ways to generate more value for your company.

What Makes Datex Different?

1. Revolutionary low code/no code flexible workflow-driven warehouse management software

2. Most configurable, user-friendly WMS on the market today

3. End-to-end solution provider: software, hardware, EDI, and managed services

4. White Glove Concierge Service

5. Executive-level attention and oversight

Industry Specific WMS

Resources

Cross Docking Definition: How Does Cross-Docking Work (bluecart.com)

Capitalizing on Cross-Docking – Supply Chain 24/7 (supplychain247.com)

Cross-Docking: Bypassing Storage – Multichannel Merchant

What is cross-docking? – Definition from WhatIs.com (techtarget.com)

When to Utilize Cross Docking – Cross Docking 101 | Datex Corp

Enhancing Cross-docking Efficiency – Inbound Logistics

The Rise of Cross Docking in the Global Supply Chain | Descartes

A Solution for Cross-docking Operations Planning, Scheduling and Coordination (scirp.org)

ryder_wp_research_brief_crossdocking_021116.pdf (logisticsmgmt.com)

Cross-dock or last mile warehouse (linkedin.com)

The Importance of Last-Mile Facilities in the Supply Chain | SupplyChainBrain