By following seven simple steps pharmaceutical manufacturers can improve supply chain efficiency and recognize additional overall revenue. These seven steps include:

- Upgrade Technologies

- Improve Product Traceability

- Implement or Increase Quality Control Processes

- Review Labor Standards

- Review Overall Supply Chain Performance

- Improve Collaboration

- Evolve towards Omni Channel

Implementing a functionally robust WMS will allow you to perform these seven steps much more efficiently than when done manually. This will also ensure reduced manual data errors which can cost your facility precious time and money.

To learn more about how to implement a WMS to make your pharmaceutical supply chain more effective and efficient contact Datex today marketing@datexcorp.com or 800-933-2839 ext 243. Datex is an industry leading supplier of supply chain solutions including WMS, mobile solutions and professional and managed services.

See what Datex Footprint® WMS can do for you.

Order Fulfillment Expectations

As omni-channel retail networks become more complex and customer’s demands advance it is important to understand both your customer’s expectations and how your supply chain business performs the functions necessary to meet those expectations. Understanding retail…

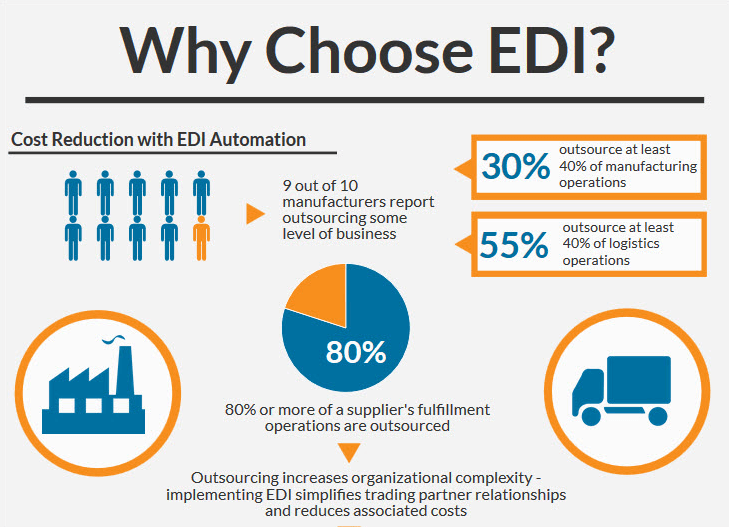

Infographic- Why Choose EDI?

Many supply chain operations are opting toward eliminating communication methods of the past such as fax, email and mail for placing orders, sending invoices and much more. This is where electronic data interchange (EDI) comes in. As more and more tasks are outsourced…

Manufacturing Outlook 2014- The Future of Manufacturing

The state of the manufacturing industry is constantly evolving to adapt to customer demand, technology advancements and a variety of other factors. To effectively handle the changes in the marketplace manufacturing businesses are making changes to their operation. In…