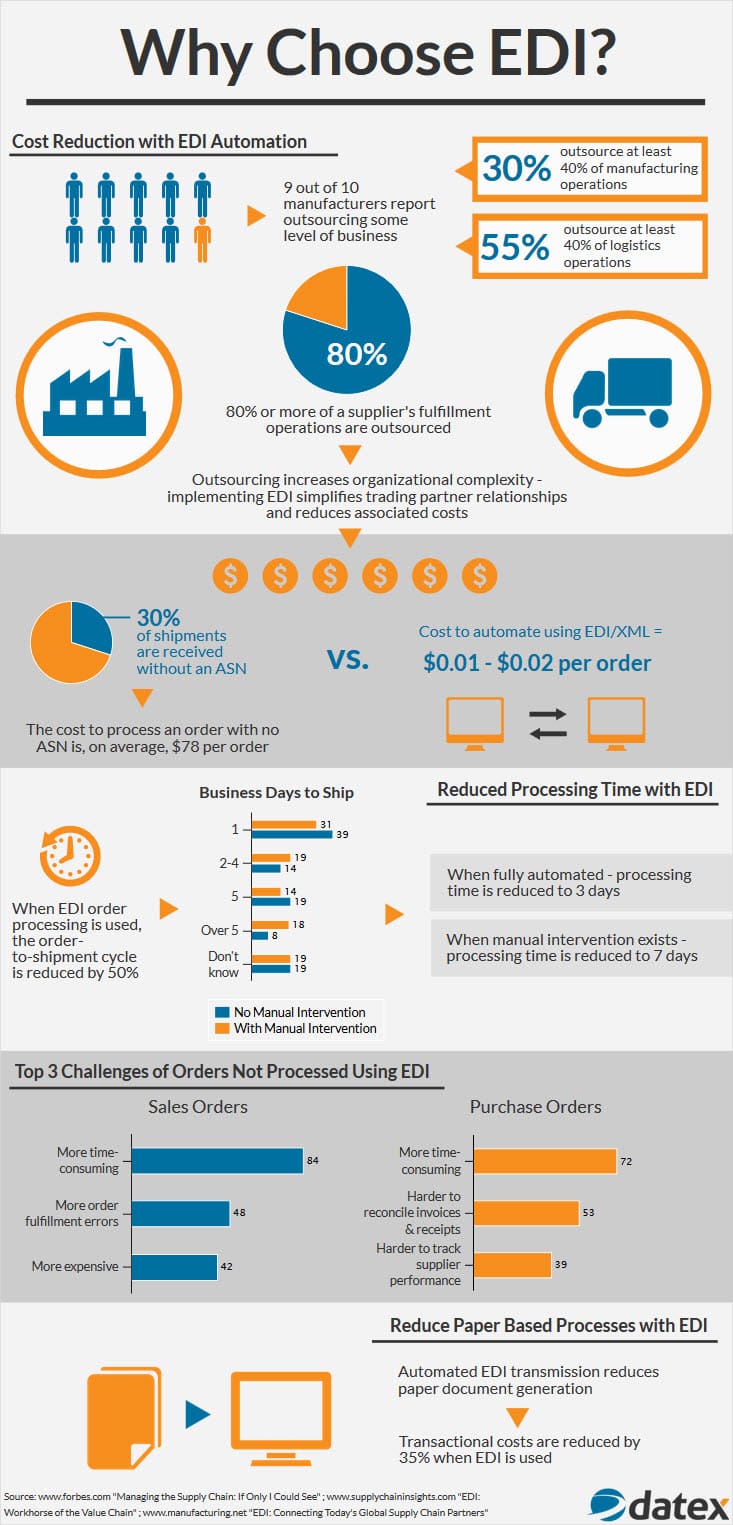

As more and more tasks are outsourced and spread throughout the supply chain, the need to communicate quickly and effectively becomes more critical. Currently, nine out of ten manufacturers surveyed are outsourcing some portion of their business, mainly manufacturing, logistics and fulfillment. This increases organizational complexity. In an effort to simplify the trading partner relationship, supply chain operators are implementing EDI to automate communication and aid in cost reduction. The cost to process an order manually is, on average, $78.00 per order. This is due to the manual data entry required to enter order details and check on availability of items before order verification. When using advance shipping notices transmitted via EDI this same order can be processed for only one or two cents. Not only is the cost to process the order reduced, but the time it takes to process and ship that order as well. This time can be reduced by up to 50% when processed using EDI.

Supply chain operations worldwide are benefiting from the time and cost benefits received from electronic data interchange implementation. Improve processing times, reduce costs and make the best of your trading partner relationship with this addition to your supply chain technology portfolio.