Reverse logistics, a key function of the supply chain, is a complex and often difficult to navigate process. This is because as the supply chain evolves and increases in complexity as a whole, so does reverse logistics. This process also contains a subset of different service offerings that vary by supply chain such as remanufacturing and refurbishing. As a general concept reverse logistics is the management of the flow of materials from the point of consumption (consumers) to the point of origin (manufacturer) for the purpose of recapturing value or disposal. Supply chain operators are focusing on the efficiency of reverse logistics more than ever as return volumes rise to nearly $200 billion annually due to the growth of online shopping. Managing this process can equate to an average of 7-10% of the total cost of goods. The significant financial impact has driven more 3PLs, warehouses and distribution centers to add this as a core competency rather than a specialized add-on service. Becoming experts helps to save their customers time and money, increasing overall customer satisfaction.

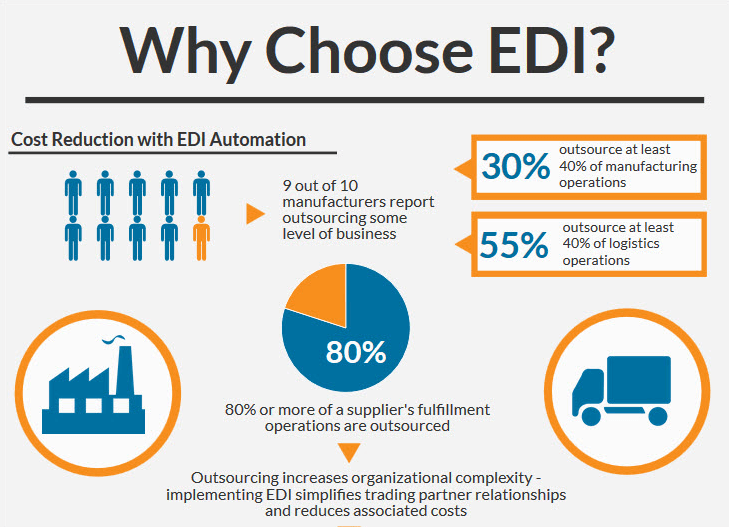

In an effort to assist supply chain operations perfect their reverse logistics processes the Supply Chain Council has developed the SCOR model which identifies 8 common return points that businesses should consider when developing their reverse logistics initiatives. These return points include: three at the supplier and supplier’s supplier level, two at the manufacturing level and three at the customer and customer’s customer level. Once these critical points have been identified and optimized supply chain businesses can benefit from well executed reverse logistics operations. The most often reported benefits of efficient reverse logistics processes are reduced remanufacturing costs, improved customer experience, maximized return on assets, streamlined operations, improved inventory management and efficient product recall execution. Many businesses turn to technology investment to assist in process optimization. Retail and manufacturing operations alike are investing in automated material handling equipment, bar code technologies, computerized return tracking and entry, EDI and RF. Relieve the financial burden of returns processing by closely evaluating your individual operations and needs and invest in appropriate technologies. To learn more about managing reverse logistics with supply chain technology contact Datex experts today at www.datexcorp.com or marketing@datexcorp.com or call 800.933.2839 ext 243.