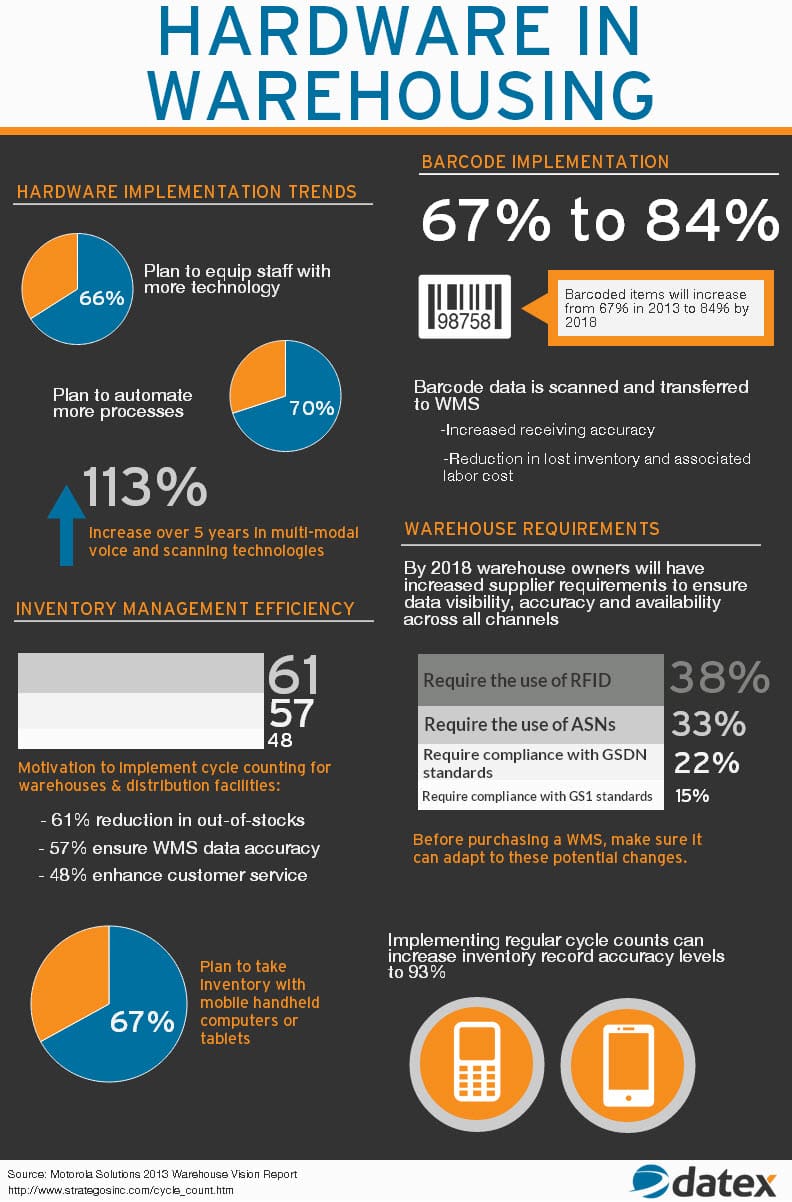

Automated data collection technologies have been gaining popularity in the warehousing, distribution, 3PL, manufacturing, retail and many other industries with physical inventory. Industry leading supply chain hardware vendor Motorola Solutions performed their study entitled “The Motorola Solutions 2013 Warehouse Vision Report” which gave significant insight into the status of hardware use in its current state and how this was expected to change through 2018.

This report revealed that more than half of surveyed supply chain operations planned to equip their staff with more technology solutions while nearly three fourths of all businesses planned to automate more processes using these ADC technologies. One significant process affected by the implementation of automated data collection solutions is cycle counting. Many warehouse operators would use these mobile devices to perform their automated cycle counts and would receive benefits including reduced out-of-stock scenarios, improved data accuracy and better customer service. None of this would be possible without significant improvement in inventory labelling using either barcodes or RFID. These solutions will also help warehouse staff reduce lost inventory and increase receiving accuracy, further improving the overall effectiveness of the supply chain.

Another notable change expected by 2018 include a new expected set of supplier requirements. Warehouse owners will expect their suppliers to implement RFID on inventory items, data transmittal via ASNs and GSDN and GS1 standard compliance. Before 2018 it is critical to evaluate your existing automated data collection portfolio to ensure your operation can evolve with the rest of the supply chain.