The Fulfillment Backbone Behind Fast, Personalized Meal Delivery

Meal kits have changed the way people eat at home; fast, personalized, and fresh-made. Brands like HelloFresh, Factor, and Blue Apron deliver more than meals: they’re delivering a lifestyle shift.

But behind each delivery is a complex, high-stakes operation, and cold storage 3PLs are right at the center of it all.

What’s driving the shift towards meal kits?

- Convenience without compromise: Ready-to-cook meals tailored to diet and lifestyle.

- Mass customization: Rotating menus with vegetarian, high-protein, gluten-free options.

- Shelf-life gains: Less spoilage, tighter margins, leaner inventory.

- Rising expectations: Fast delivery, fresh product, and planet-friendly packaging.

But all that flexibility creates serious complexity. Cold storage 3PLs are no longer just storing food; they’re becoming assembly lines and fulfillment hubs for direct-to-consumer brands.

Cold Storage That Builds, Not Just Stores

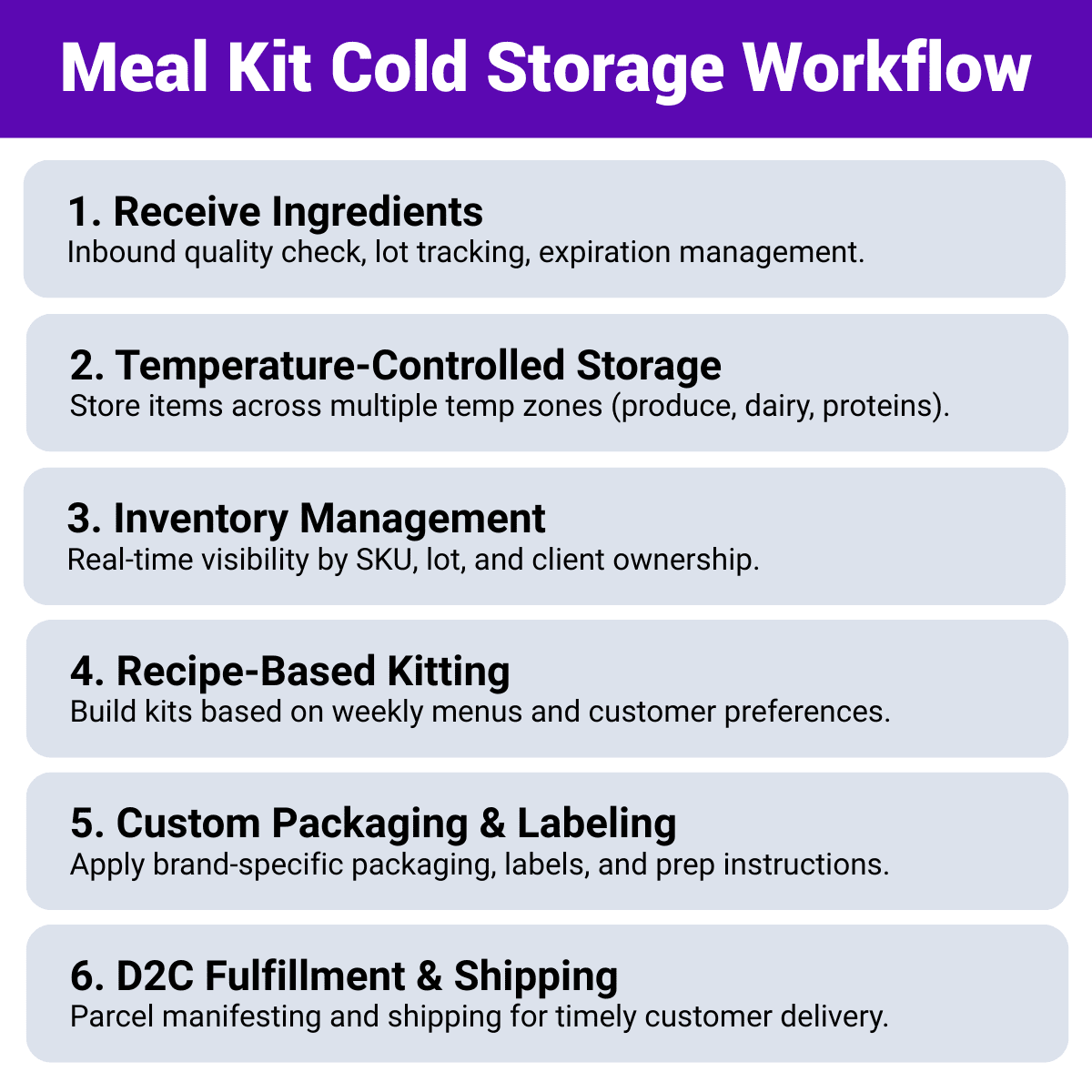

Today’s cold storage 3PLs do more than hold meal kit inventory; they’re manufacturing personalized, ready-to-ship meal kits on demand. That means handling temp-sensitive ingredients from multiple suppliers and assembling precise orders at scale. Every day, teams are:

- Verifying inbound quality and temperature

- Managing lot codes and expiration dates

- Tracking ingredients across temp zones (produce, dairy, protein)

- Building kits based on rotating menus

- Customizing orders to individual preferences

- Applying brand-specific labels and packaging

The Evolved Cold Chain: Build, Pack, Deliver

To keep up, cold storage warehouses must evolve. They need systems built to receive, assemble, and deliver with speed, precision, and food safety locked in.

- Ingredient-level traceability with lot and expiration tracking from dock door to doorstep.

- Dynamic kitting based on rotating menus.

- Multi-temp zone management keeps ingredients stored and picked across refrigerated, chilled, and ambient zones.

- Automated freshness rotation (FEFO) and auto-rotation ensure nothing ships past its prime.

- Multi-client inventory maintains clear separation between brands and inventory owners.

- Direct-to-consumer labeling and shipping.

- Audit-ready compliance (FSMA, USDA, CFR 21 Part 11).

Meal kit warehouses do it all, from receiving cold ingredients and assembling kits on demand, to shipping direct to consumers daily. With Datex Footprint® WMS, cold storage 3PLs get the visibility, flexibility, and control to stay ahead, making it easier to handle this complexity with confidence.

Meeting Meal Kit Demand with Smarter Cold Chain Logistics

Meal kit demand is skyrocketing, demanding a parallel surge in temperature-controlled warehouse operations with precise inventory control, dynamic kitting workflows, and seamless D2C fulfillment.

With global meal kit revenue expected to almost triple by 2030, and cold chain investment growing similarly fast, warehouses that receive temperature-sensitive ingredients and convert them into customized meal kits will define logistics leadership.